Ratis 1X stage

Ratis 1X single axe nano piezo scanning stage

Ratis 1X

- Low cost

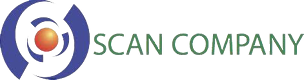

- Compact design

- Suitable for universal applications

Piezo stages are made of solid metal bulk processed with EDM wire-cutting and precise CNC machining. Movable central part hangs on flexible springs and is driven with piezo actuators. Ratis design provides excellent linearity and flatness of the movement, in contrast to the classical scanners based on piezoelectric tubes, where the scan surface is a sphere. In addition, plane-parallel scanners have higher mechanical strength, compared with fragile piezoelectric tubes.

Ratis 1X

multi-axes scanners are equipped with optical sensors for digital closed-loop control. It provides high accuracy and linearity of movement and eliminates the creep effect of piezoceramics.

It provides high accuracy and linearity of movement and eliminates the creep effect of piezoceramics.

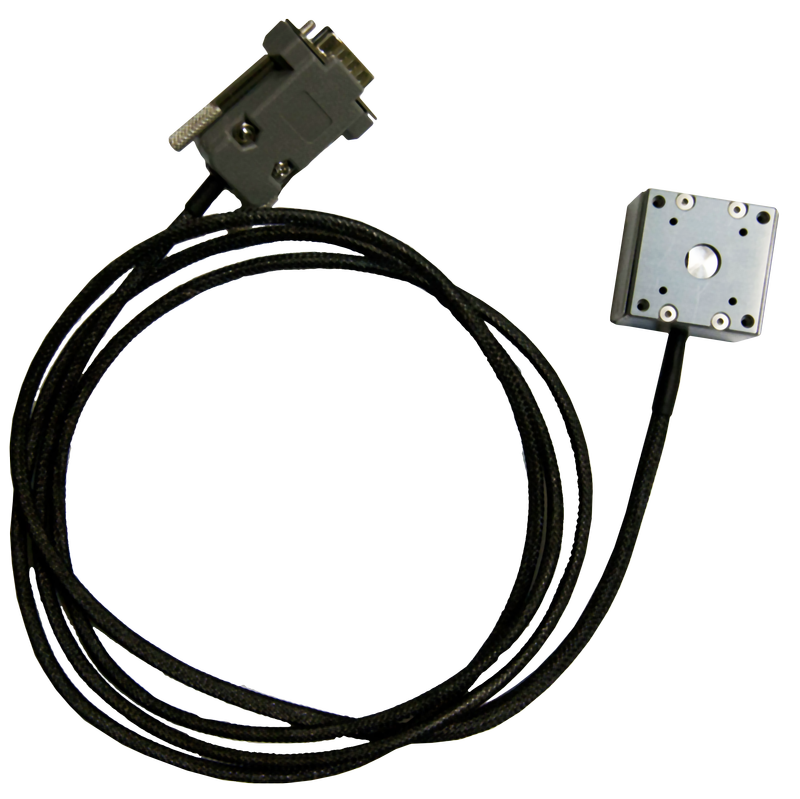

To control Ratis 1X piezo stage universal controllers EG-1100 are used as well as NSpec software.

Applications of Ratis 1X include scanning probe microscopy (e.g. atomic force microscopy), nanopositioning, metrology, biology research, microelectronics, micromanipulation etc.

Optical sensors is used, which greatly improves sensors quality.

Specification:

| Parameters | RatisSPM XYZ |

|

| XY travel range (Closed-Loop), µm | - | |

| Z range (Closed-Loop), µm | 120 |

|

| Resonant frequency XY, kHz | - |

|

| Resonant frequency Z, kHz | 3 |

|

| Accuracy, nm | 1 |

|

| Angle tilting over the full range, nm | < 0.01° | |

| Maximum scanning speed, Hz (line/sec) | 10 | |

| Base sample weight, g | 100 | |

| Operating temperature range | at -40°C to 80°C | |

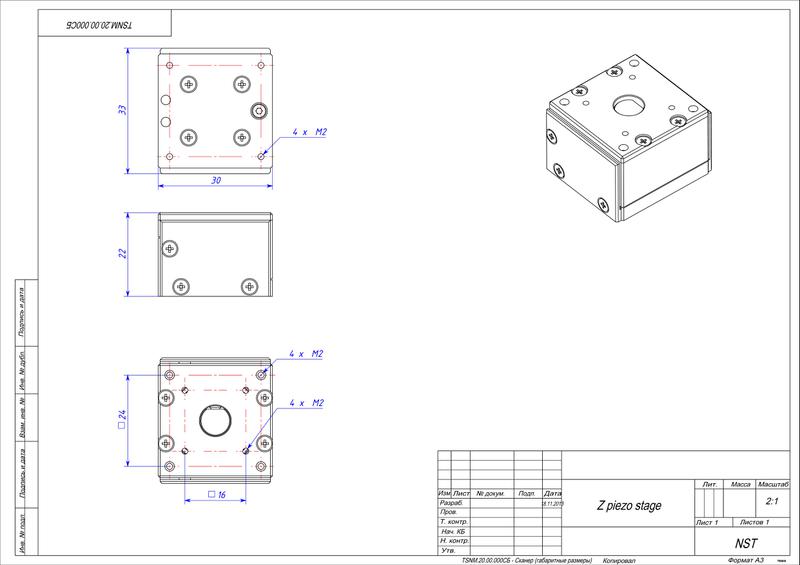

| Dimensions, mm | 33×30×22 | |

| Material | Aluminium | |